Delivery mistakes don’t just slow you down, they jam up job sites, frustrate customers, and throw your whole day off balance. Anyone who’s ever sent a driver to the wrong gate at a refinery or watched a pallet of HVAC parts land at the wrong address knows the pain. But here’s the good news: most delivery errors aren’t mysteries. They’re predictable. And with the right tools, training, and mindset, they’re avoidable.

At Gophr, we treat error prevention like a mission, not a maybe. Because when your business depends on getting materials, parts, or paperwork exactly where they need to go, “close enough” isn’t close at all.

The Most Common Delivery Mistakes (and How to Dodge Them)

Most delivery errors fall into a handful of categories: simple, human, preventable. Think of them like the potholes of the logistics world, you can’t fix them all, but you can avoid every single one if you know where they are. Some of the biggest offenders include:

Wrong address or incomplete instructions

Tiny details cause big headaches. Missing suite numbers, unclear gate codes, or “back entrance only” not being passed to the driver.

Miscommunication between teams

Sales says one thing, operations hears another, and the driver gets something else entirely.

Lack of delivery visibility

If you don’t know where a shipment is, you can’t correct an issue before it lands in the wrong spot.

Poor packaging or missing handling requirements

A forklift delivery without a forklift available. A heavy pallet with no liftgate selected. It happens more often than it should.

Untrained or inconsistent drivers

When your provider is sending “whoever is available,” reliability becomes a roll of the dice.

Tools That Make Error-Free Deliveries Possible

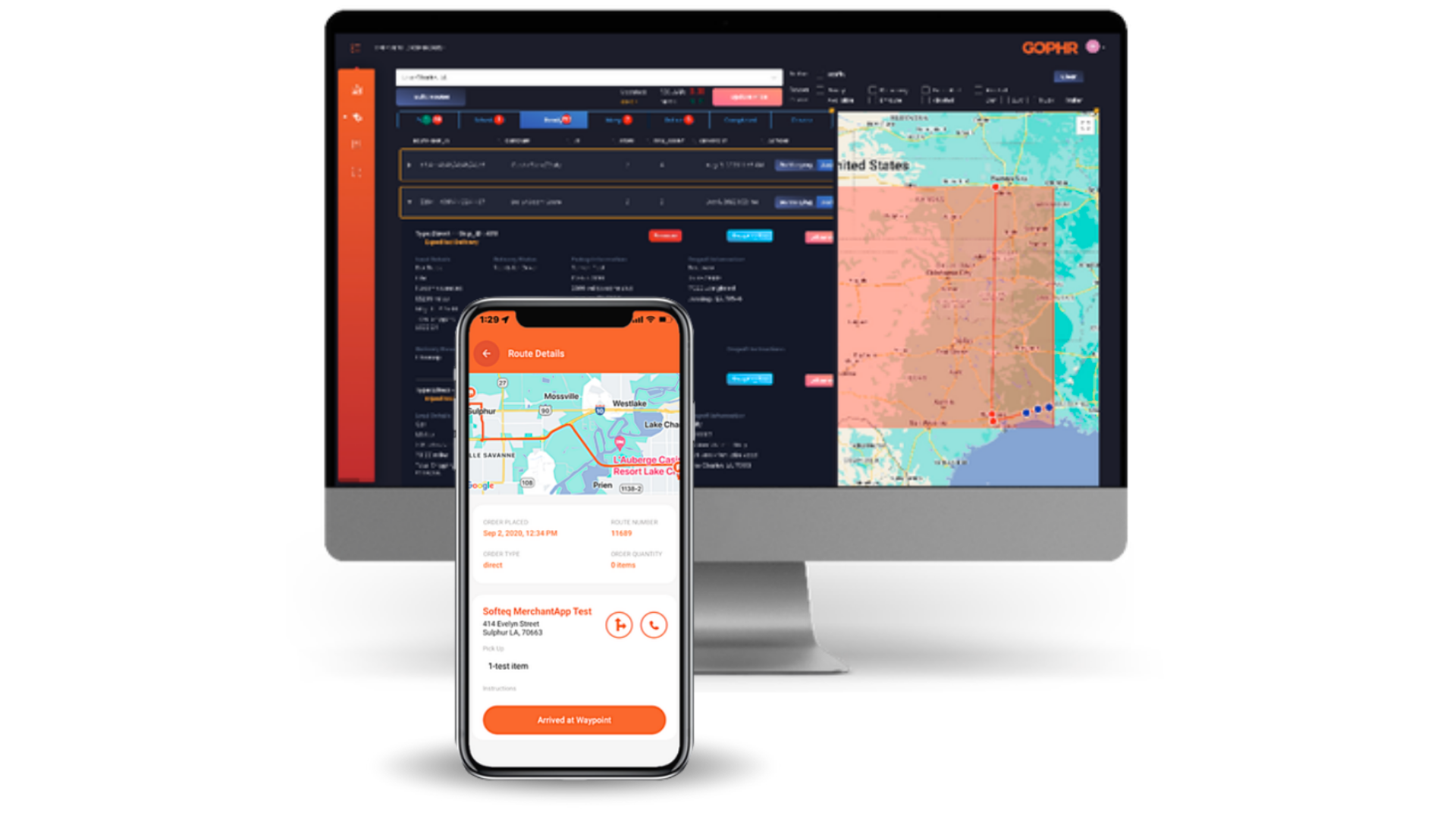

Modern logistics lives and dies by its tools. That’s why Gophr built its platform for real-world crews, not Silicon Valley daydreamers.

Here’s what keeps mistakes from becoming your problem:

Real-time tracking and transparency

Customers can see every stop, every turn, and every timestamp. This level of visibility calms chaos and makes problems fixable before they snowball.

AI-powered dispatching

Smart route optimization cuts down on wrong turns, wasted miles, and last-minute scrambling.

Digital BOLs and photo proof of delivery

No guessing. No “he said, she said.” Every order ends with clarity.

Equipment and tool selection inside the dashboard

Need a liftgate? Dolly? Fork truck? Drivers see exactly what’s required before arriving, reducing on-site errors dramatically.

Vetted, trained, insured drivers

Not “just whoever’s nearby.” Gophr prioritizes professionals who know industrial delivery standards.

How Gophr Minimizes Delivery Errors (On Every Run)

Plenty of companies talk about reliability. Gophr operationalizes it.

Here’s how we keep your delivery error rate low:

Extreme ownership at every stage

Our operations team doesn’t ghost or make excuses. We own the result, every time.

Clear communication, start to finish

Updates, notifications, and real-time visibility mean no one is left guessing.

Standardized workflows through the Merchant Dashboard

Whether it’s a single drop, a routed run, or multidrop chain, every order uses the correct format. This reduces guesswork and confusion.

Specialized handling for industrial assets

Drivers are trained and credentialed to handle the heavy, fragile, or high-value items that traditional couriers mess up.

No “chaos gap” between departments

Because Gophr serves industrial, construction, supply, and energy teams, we built systems that prevent the classic breakdown between the jobsite, the warehouse, and the dispatcher.

Training That Builds Reliable Delivery Performance

A flawless delivery doesn’t start at the wheel, it starts upstream.

Gophr’s training focuses on:

Site-level awareness

Understanding refinery gates, job-site protocols, and industrial expectations.

Equipment readiness

Knowing when liftgate, dolly, or fork truck assistance is required, and confirming it before arrival.

Document accuracy

Drivers are trained on secure BOL handling, signature requirements, and compliance.

Problem-solving without panic

Cool under pressure, very Keanu of us, but it’s true. Gophr drivers are trained to adapt fast without improvising wrong.

Steps Any Business Can Take to Ensure Flawless Deliveries

Whether you’re shipping valves, wire, scaffolding, pharmaceuticals, or a time-critical part your team needed yesterday, here’s how to minimize errors on your end:

- Double-check pickup and drop-off instructions

Gate codes, building access, job-site contacts—these matter. - Provide handling requirements upfront

If heavy, fragile, or specialized gear is involved, note it. - Use a delivery partner with transparency tools

If you can’t see the delivery, you can’t control the outcome. - Consolidate communication

Use one system, one thread, one source of truth. - Choose trained, professional drivers—not random gig workers

Your cargo shouldn’t be practice for someone’s first day.

Final Takeaway

Delivery errors cost real time, real money, and real trust. However, they’re preventable when the right tools, training, and mindset meet real-world discipline. Gophr was built to be the dependable answer logistics teams have been looking for: calm, clear, and competent, every mile of the way.

If flawless deliveries matter (and they do), then it’s time to roll with a partner who treats your cargo like their reputation’s on the line, because that’s exactly how we operate.